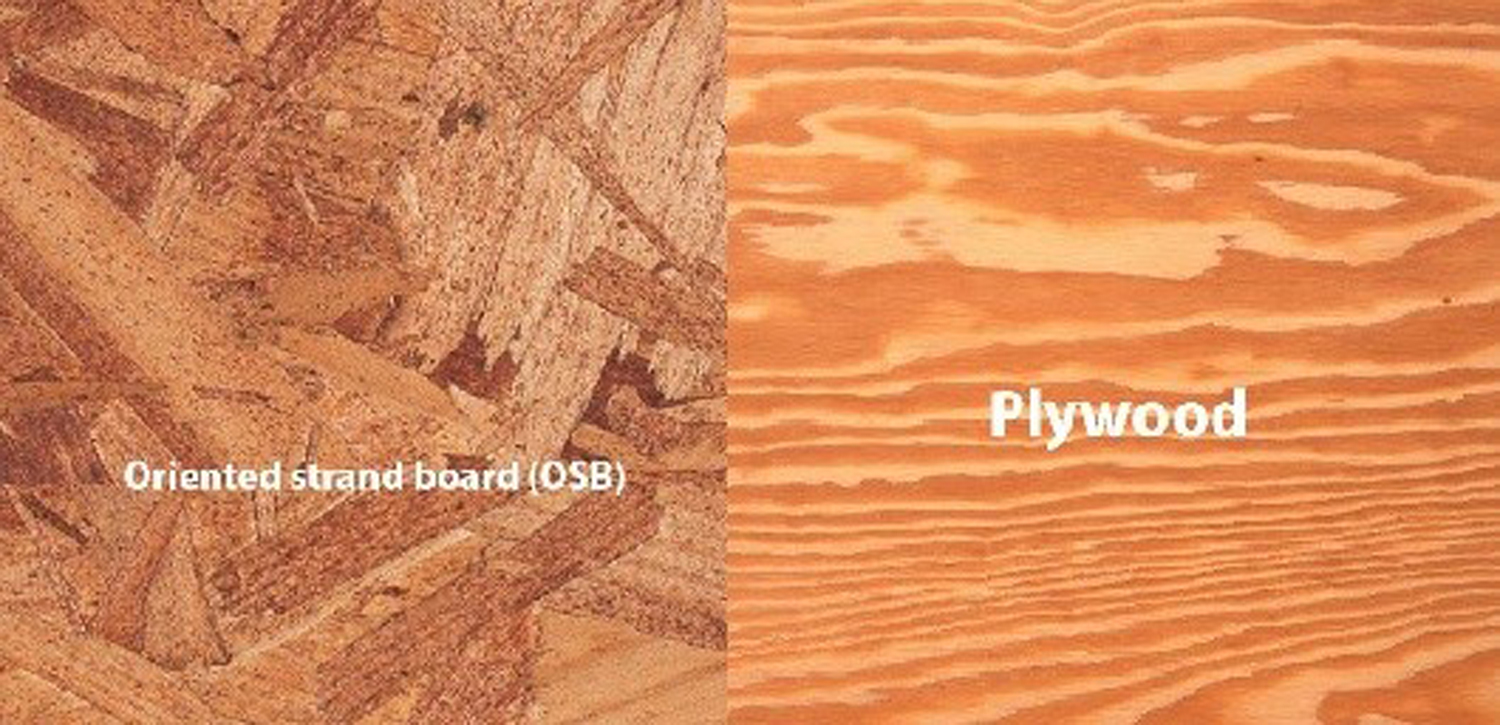

When it comes to structural wood panels, there are two products that instantly come to one’s mind, oriented strand board (OSB) and plywood. Both of these panels are made by compressing and gluing pieces of wood together. While plywood and OSB appear similar and are generally interchangeable, each one is manufactured different and the manufacturing process contributes to their own unique strengths and weaknesses.

OSB is manufactured from heat-cured adhesives and rectangular shaped wood strands that are arranged in cross oriented layer. It is a solid panel product of consistent quality with few voids or gaps that is produced in large, continuous “mats”. There are approximately 50 layers of strands in one sheet of OSB. The finished product is an engineered wood panel that shares many of the strength and performance characteristics of plywood.

Plywood is made from thin sheets of veneer (layers of wood that are peeled from a spinning log) that are cross laminated and glued together with a hot press. Throughout the thickness of the panel, the grain of each layer is positioned perpendicular to the adjacent layer. The finished product is made from and odd number of layers so that the balance is maintained around it central access. Since it is made from whole layer of logs rather than small strands, plywood has a more consistent and smoother appearance than OSB.

It can be a tough decision deciding whether to use OSB or plywood on a project. Below is information on both products that could be helpful in the decision making process:

- OSB can be manufactured into panels that are larger than plywood panels. 90% of all plywood manufactured comes in 4X8 sheets.

- OSB is more uniform, so there are fewer soft spots.

- OSB is less expensive than plywood. It typically sells for $3-$5 less per sheet. If you use OSB for a typical 2,400 square foot house, you will save $700.

- Some consider OSB to be a “resource efficient” building material because it is made from smaller diameter trees that are often farmed. The process also maximizes the amount of wood fiber from each tree. Plywood requires larger diameter trees typically found in old growth forests.

- OSB is stronger than plywood in terms of shear strength. Shear values through its thickness are about two times greater than plywood.

- Plywood is lighter in weight than OSB. A 23/32 plywood panel weighs 2.2 pounds per square foot compare to 2.4 pounds per square foot for an OSB panel.

- Plywood is more moisture resistant and has a faster dry time than OSB.

- Plywood is stiffer than OSB. A plywood panel bending stiffness is 10% greater than OSB. Plywood is the better choice when it comes to underlayment for flooring as OSB panels will more than likely result in soft spongy floors, squeak due to floor movement, and cause hard floor surfaces, such as tile, to crack.

- Plywood has a tendency to have panel voids. This is a result of the thin sheets that are laminated together to make a plywood panel having soft spots. The voids are often noticeable if you take a quick glance at the edge of a plywood panel.

Both types of panels meet the national and local building codes. Ultimately the decision on which product to use come comes down to preference and application. Until next time my friends, be prepared and stay safe.

Reference: “Product Pros and Cons: Oriented Strand Board vs. Plywood” by Nigel Maynard and “OSB vs. Plywood” by Nick Gromicko